AL Ghadhban Lubricant Waste Recycling Plant

welcome to

al ghadhban lubricant waste recycling llc

AL Ghadhban Lubricant Waste Recycling Plant, your premier destination for sustainable waste management and environmental protection in Dubai, UAE. Situated in Dubai Industrial City, near the bustling port of Jebel-Ali, our state-of-the-art facility stands as a beacon of innovation and commitment to a greener future.

Many Years Of Undefeated Success

The AL Ghadhban lubricant waste recycling plant in Dubai is a

state-of-the-art facility, located in Dubai industrial city, near the

port of Jebel-Ali, UAE, dedicated to sustainable waste

management and environmental protection. Strategically located

in Dubai, this advanced plant boasts all the necessary licenses

and permits in place, ensuring compliance with stringent

regulations and standards for waste recycling of Dubai state

authorities and Dubai municipalities.

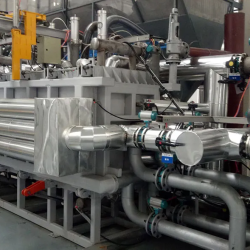

Cutting-Edge Technology

Explore our innovative approach to waste management.

Strategic Location

Discover the benefits of our Dubai Industrial City location.

Compliance Assurance

Learn about our commitment to meeting and exceeding regulations.

Tailored Solutions

Find out how we customize services to fit your needs.

Processing Capacity

70 Matric Tonnes Per Batch

EFFECIENCY AND SCALE

The processing capacity of 70 metric tonnes per batch positions the plant as a highly efficient and large-scale facility capable of managing substantial volumes of marine oil and lubricant waste.

ENHANCED PRODUCTIVITY

This level of capacity ensures enhanced productivity, enabling the effective recycling of a significant amount of waste material in a single batch, leading to resource optimization and costefficiency.

OPERATIONAL FLEXIBILITY

With a processing capacity of 70 metric tonnes per batch, the plant can accommodate diverse waste streams, promoting operational flexibility and the ability to handle varying types of marine oil and lubricant waste.

Recycling Process & Technology

WASTE COLLECTION AND SORTING

At the marine oil and lubricant waste recycling plant in Dubai, the process begins with the collection of marine oil and lubricant waste from various sources, including ships, oil rigs, and industrial facilities. The collected waste is then sorted based on its composition and origin to ensure proper recycling methods are applied to each type of waste. The sorting process involves meticulous inspection and categorization to determine the best approach for recycling, minimizing contamination and maximizing the yield of reclaimed materials.

ADVANCED TREATMENT & PURIFICATION

Once sorted, the waste undergoes advanced treatment and purification processes using state-of- the-art technology and equipment. This includes filtration, centrifugation, and specialized chemical treatments to remove impurities and separate the different components of the waste. The goal of this stage is to extract usable oils and lubricants from the waste while ensuring that the resulting products meet stringent quality standards and environmental regulations.

RECOVERY & RECLAMATION

After purification, the reclaimed oils and lubricants are recovered and prepared for reuse. This includes further refining, blending, and testing to ensure that the recycled products are of high quality and suitable for a wide range of applications within the marine and industrial sectors. The recycling process is designed to minimize waste, reduce the environmental impact of oil and lubricant disposal, and contribute to a more sustainable and circular economy in the marine industry.

Why Choose Us

Innovation: Our facility is at the forefront of technological advancements in waste recycling, ensuring efficiency and effectiveness in our processes.

Expertise: Backed by a team of industry experts, we bring years of experience and knowledge to every project.

Sustainability: We are committed to a greener future. By choosing AL Ghadhban, you are contributing to a more sustainable world.

Our Commitment

At AL Ghadhban Lubricant Waste Recycling Plant, we are not just a company; we are a catalyst for change. Join us in our journey towards a cleaner, greener tomorrow.

Get in Touch

Ready to make a difference? Contact us today to learn more about our services and how we can help you with your waste recycling needs.